Detecting wear and tear as well as production errors

eDrive units are tested intensively before series production, in many cases driven for weeks or randomly. The Discom durability test is used to check eDrive prototypes for wear and tear as well as for possible design weaknesses.

Repeating typical drive cycles continuously

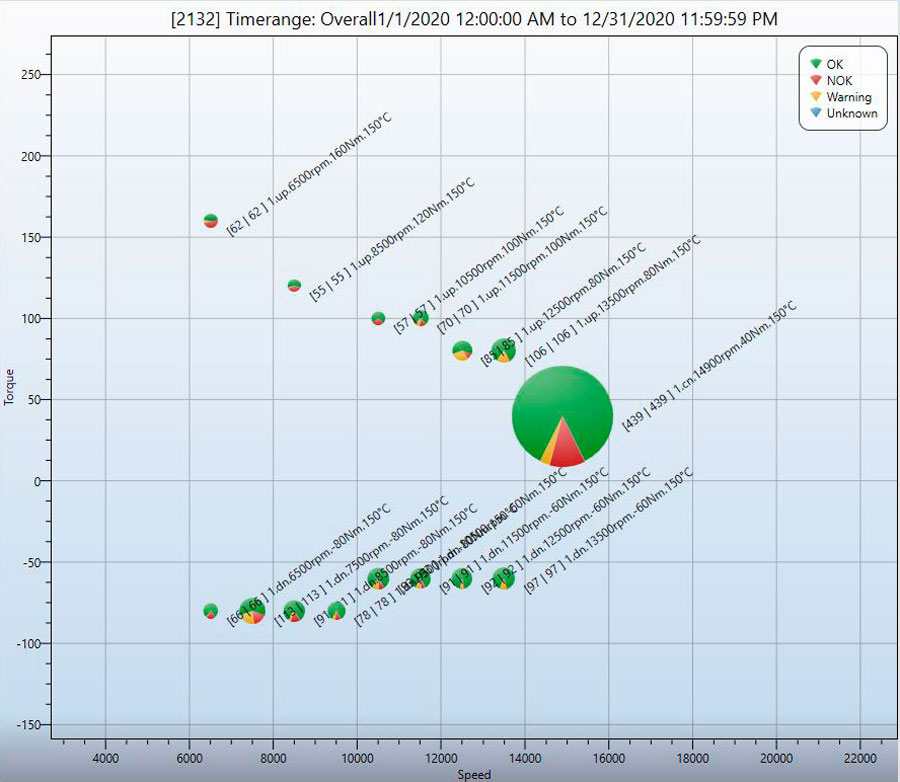

In durability testing, typical drive cycles are repeated continuously, for example accelerating, driving straight forward, coasting and energy recovery during braking. The Discom Marathon software automatically detects recurring sections with comparable test conditions from rotational speed and torque, even in non-periodic test cycles. All measurement results are assigned to their test conditions. Thus the analysis of trends compares automatic segments with stable test conditions from rotational speed and torque such as driving at a constant speed or ramps. The temperature is also acquired and taken into account.

Marathon:

Discom complete solution for durability testing

Discom offers the complete solution for durability testing, “Marathon.” It consists of sensors, frontend, PC rack and software. In this solution the test specimens are fitted with vibration transducers. Data from the test specimens is digitized in the TAS frontend, the Discom data acquisition system. In the measurement PC they are forwarded to the MaraView analysis tool. The frontend TAS48 provides up to 16 sensor channels and four inputs for rotational speed encoders. Additional data can be acquired via CANbus.

MaraView software

This software suite is a powerful tool for R&D departments for analyzing and evaluating durability tests precisely – online and offline. Discom has developed a dedicated analysis software tool for the special requirements of trend analysis in an durability test: MaraView. The software is based on the well-established TasAlyser analysis software with a results database. With this software, it is possible, among other things, to analyze trends and detect developing damage and changes to various operating conditions at an early stage.

Production analysis

WebPal Production Statistics from Discom helps users to track trends, allowing them to detect problems that will occur at an early stage, before they become a true problem.

Your benefits

Your benefits

Evaluate durability tests reliably

- Comprehensive analysis of test specimens in a durability test

- Reliable statements on aging and wear in the durability test

- Unambiguous pinpointing of problems and damage

- Marathon software for durability testing with the MaraView analysis tool

- Combination with electrical analyses via the “Genesis HighSpeed” data/transient recorder from HBM

Your advantages

Your advantages

Development of successful products for the market

- Durability testing with the Discom system provides assurance that the eDrive units will work in real-life conditions

- Prevent complaints at an early stage

- Technological lead over the competition

- Success on the market

Additional insight information:

Power meter and data acquisition system for testing electric drives

The combination of acoustic and electrical analyses provides additional information about the test specimens during the durability test. Marathon can be connected with the transient recorder “Genesis HighSpeed” from HBM. This is a modular DAQ system for fast measurements of electrical and mechanical quantities. It combines a transient recorder, data recorder and data acquisition system in one device. This makes it possible to measure and analyze electrical parameters of the motor. For example, it can be used to measure how much power the electric motor feeds into the drive and how much heat is lost. This information is supplied to the software and integrated into its analyses and evaluations. More information can be found here.

Downloads

Info sheet endurance test and marathon system

Have we caught your interest?

Do you have any questions?

Would you like a consultation?