Analysis of the measurement data: identifying NVH sources reliably

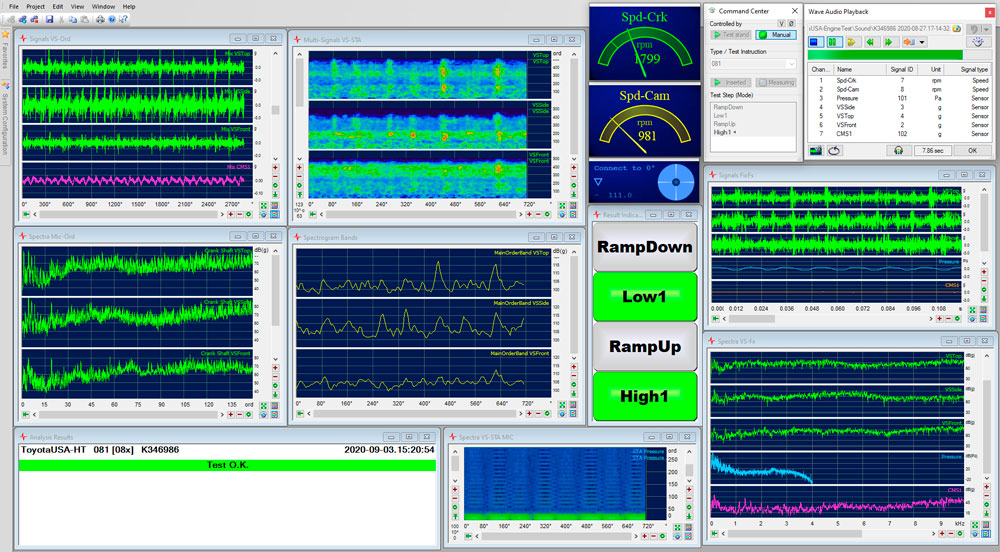

The core element of the Discom Software Suite: TasAlyser is the leading measurement application for analysis and live evaluation of acoustic and speed data in end-of-line testing. The software processes and analyzes the sensor data from the TAS frontend and displays it in real time as a graphic. This software accurately identifies NVH sources.

Quality monitoring in real time

The TasAlyser software is used for reliable monitoring of manufacturing quality in real time. The user is notified immediately of production faults and exceeding of defined limits by plain text rejection messages. This makes it possible to react to production faults immediately.

TasAlyser capabilities

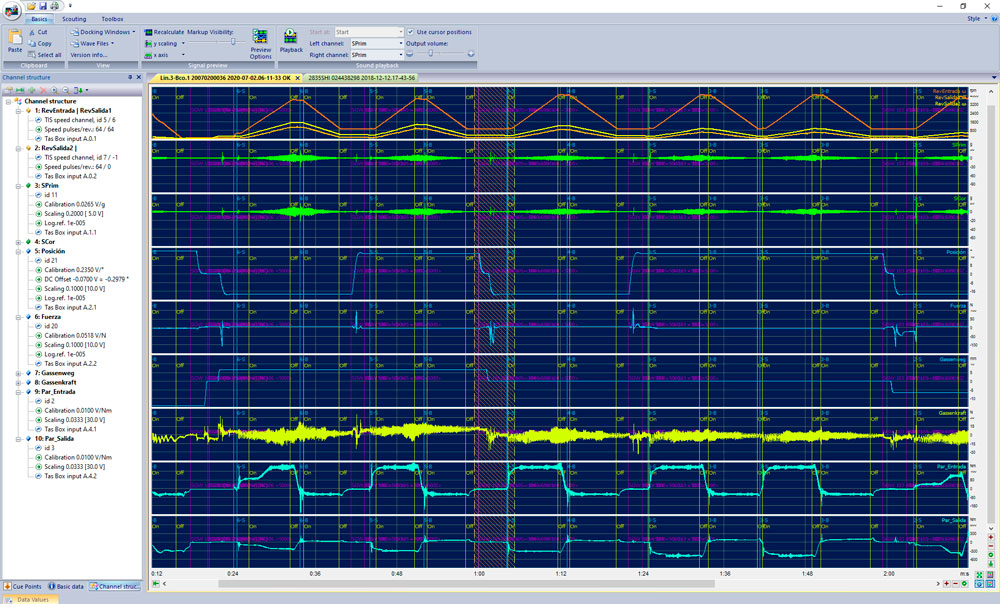

- Sensor data processing: Order and frequency spectra, rotationally synchronous order analysis, level curves over rotational speed or torque, analysis of durability tests and individually configurable analysis modules

- Define limit values and test whether they are exceeded

- Acquisition of the serial number and other test specimen data

- Communication with test bench control: access status information, transmit analysis results

- Raw sensor signals available for listening and re-analysis

- Data storage and exchange with external analysis systems

Integration into the test bench via standardised interfaces

TasAlyser runs on the Discom PC rack directly in the control cabinets in the test bench. The analysis software uses a reliable, flexible and expandable communication protocol for the exchange of information with the test bench control unit. Widely used interfaces including Profibus, Profinet, CANbus, RS232 and UDP are available. For old test benches or try-out installations, the test runs can be controlled by automatic recognition of the test profile stages.

Your advantage: The hardware interfaces and communication protocols are well established in production.

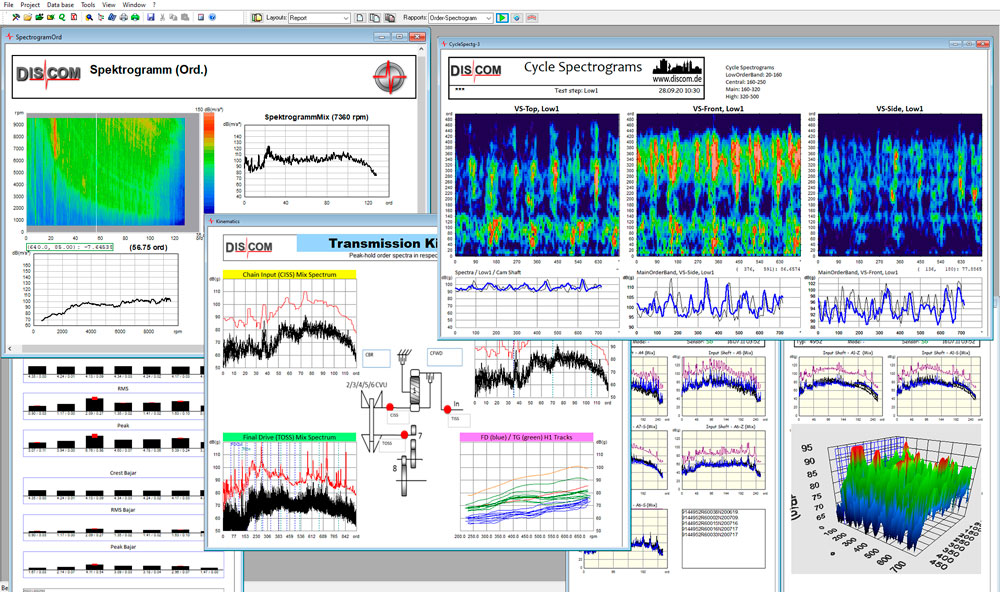

Marvis: Detailed analysis and reporting

The “Marvis” software module analyzes and compares results in detail. It reads the result files generated by TasAlyser directly as files or from the results database. Marvis can also be used to generate printable reports with freely configurable layouts

Your advantage: Marvis provides detailed examinations of NVH sources and generates printable measurement reports ready for distribute.

Parameter database and network: Centralised management of test benches from an office PC

Discom measurement technology is designed for operation in production with a large number of test benches. TasAlyser manages all parameters for analysis, evaluation and limit value in one central parameter database. This database also contains the kinematics model of the test object, which makes it possible for TasAlyser to calculate the characteristic frequencies for each noise source. The database can manage multiple production lines and different models simultaneously. This makes it possible to parameterize test specimens centrally from a computer or server.

Your advantage: Management, parameterization and analysis can be performed centrally from an office PC without having to physically access test benches or servers.

Measurement data archive: Storage of results for decades

Every measurement analyzed by TasAlyser is stored. All measured values, curves, spectra, tracks and other results, including their limit values, are stored in result files (measurement archives). These files can be analyzed with the Discom Marvis software, sent via e-mail to colleagues or Discom experts and in the same time collected in the results database.

Your advantage: Complete production of multiple test benches can be stored for decades in this archive.

Wave recording: Listening to communcation

The original sensor data and rotational speed of each test run is recorded together with the test bench commands and the metadata in a wave data set in WAV format. These wave data sets can be replayed in TasAlyser, resulting in a virtual repeated test of the test object.

Your advantage: Wave recording can be used to optimize parameterization, test setup and limit value settings.

Specifications

Data sources

TAS frontend generates digital data. Additional information can be read from CANbus and synchronized with the USB data stream.

Operating system

Standard Windows 10 computers with 64-bit multi-core processors

Powerful

Extensive results database

Archive system

with preprocessed data for the SQL database

Your benefits

Your benefits

Turnkey software for customer-specific EoL testing

- One software for all evaluations of the acoustic EoL measurement

- Analysis and identification of the exact cause of noises

- Monitoring of limit values/tolerances

- Automatic operator messaging when tolerances are exceeded

- Customer-specific configurations for individual test specimens

- Easy operation with the familiar Windows operating system

- Numerous hardware interfaces

- Different language settings

- Can be used for networks: Control of all parameters from a central PC

- Communication with test bench

- Recording of measurements as a wave data set

- Data archiving for decades

- Training by Discom makes users independent

Your advantage

Your advantage

Reliable measured value analyses improve quality assurance

- Minimize rejects and complaints: With live analysis in real time, production faults are detected immediately and can be corrected without delay

- Project engineering: Individual configuration exactly coordinated with the customer’s measurement tasks, measurement evaluations and network situation

- Worldwide experience: Discom’s extensive parameter database is incorporated into every measurement project

- Lower workload: All test benches can be managed from one PC

- Measurement analyses with TasAlyser optimize parameterization, test setup and limit value settings – and thereby improve quality assurance

Have we caught your interest?

Do you have any questions?

Would you like a consultation?