Reliably localize manufacturing defects

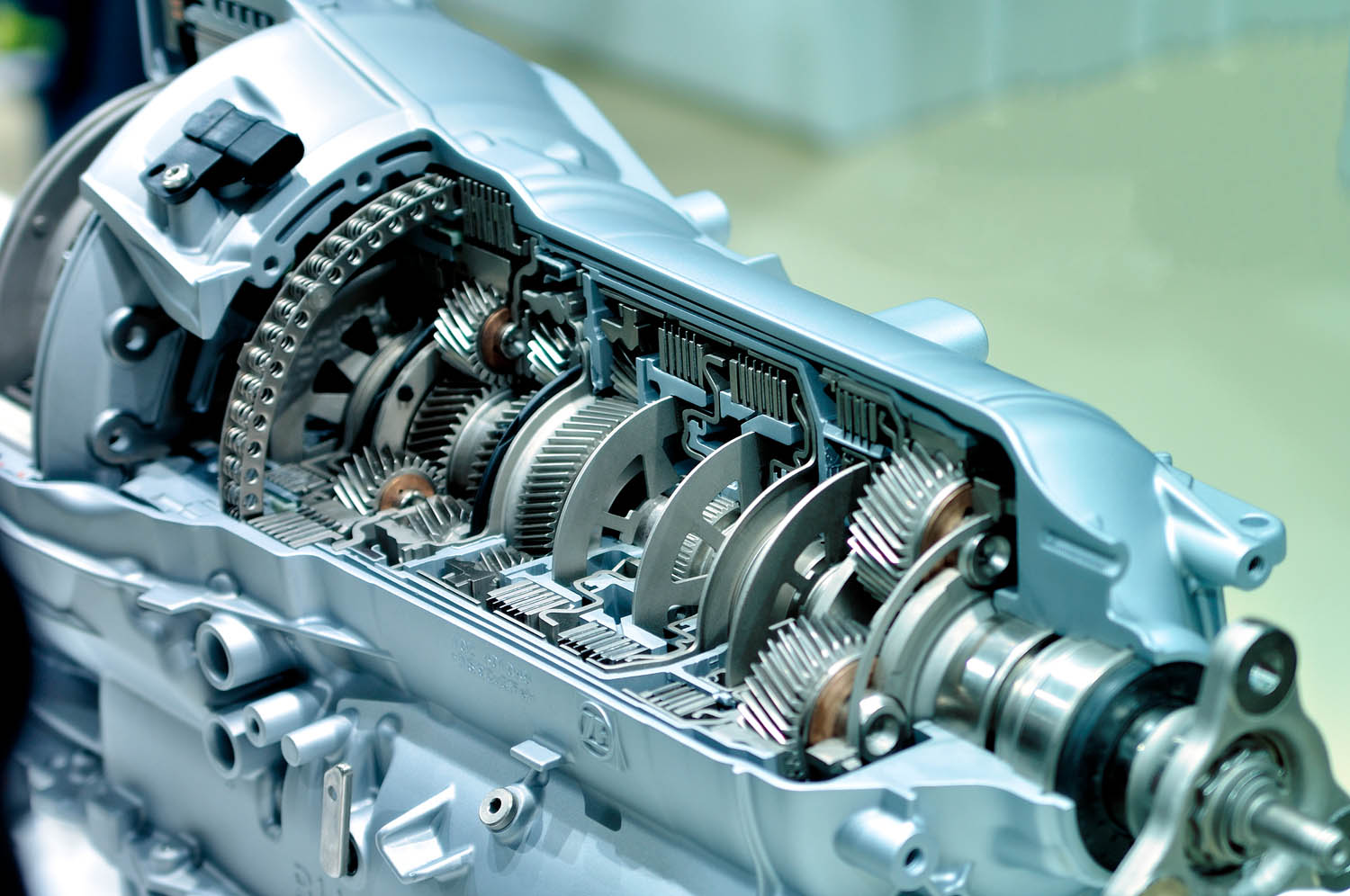

Transmissions are complex modules: It is crucial in end-of-line testing to detect manufacturing errors in gear wheels, bearings or in the shifting mechanics to be able to exclude faulty transmissions and at the same time adjust production in time. Discom “listens” inside the closed modules: We offer a proven complete solution for transmission testing, consisting of sensors and software for 100% testing in the end-of-line test bench. Discom measurement technology pinpoints a problematic gear wheel or a faulty bearing exactly and reliably.

Measurement solution for all types of transmissions

- Gearboxes

- Conventional automatic transmission

- Rear axle transmission

- Dual-clutch transmission

- CVT transmission – infinitely variable with variable drive ratio

- Hybrid transmissions with electric part

Detecting sources of errors reliably

The method of the Discom measurement solution finds errors reliably in:

- Gear wheels: Exact pinpointing and identification of a gear wheels with manufacturing errors such as surface ripples, pitch errors and damage

- Gearboxes: Switching noises

- Dual-clutch transmissions: Clutch noises

- Tapered roller and needle bearings: Production errors such as ripples in the bearings

Sensors and frontend

Transmission testing is carried out with one or more BKS structure-borne sound sensors. Depending on space in the test bench, the general purpose sensor BKS03 or the smaller compact sensor BKS10 is used. Additional encoders acquire the rotational speed of the input and output drive of the two wheels as well as the applied torques. As an additional option, the function of the differential and the transmission drive ratio can be tested. The TAS box is the matching Discom measurement frontend.

Software

The Discom TasAlyser software uses a powerful parameter database to specify the testing methods, measured quantities and limit values. There is also a kinematic module for transmissions in the software so the characteristic frequencies can be automatically calculated and assigned to the components. Due to the evaluation software TasAlyser, the users keep track of the complex parameters of the measurements and their evaluations.

Your benefits

Your benefits

Exact pinpointing of the faulty component

- Faulty components are reliably detected and exactly identified

- Extensive testing of different transmission components: Gear wheels, bearings and switching systems

- Functionality testing, for example of the differential and drive ratios

- Powerful and highly modular TasAlyser software for analysis

- Parameter management system based on a database for application-optimized and transparent handling of all relevant characteristic quantities and a kinematic module for clearly identifying manufacturing errors

- Kinematic model to clearly identify noise source

Your advantages

Your advantages

Strengthen competitiveness on the market

- Measurement solution for 100% testing of transmissions

- Safeguard and increase the manufacturing quality of transmissions

- Investment pays for itself quickly: Lower costs by reducing manufacturing errors and expensive rejects

-

Strengthening the position on the market against competition