Most successful sensor for end-of-line

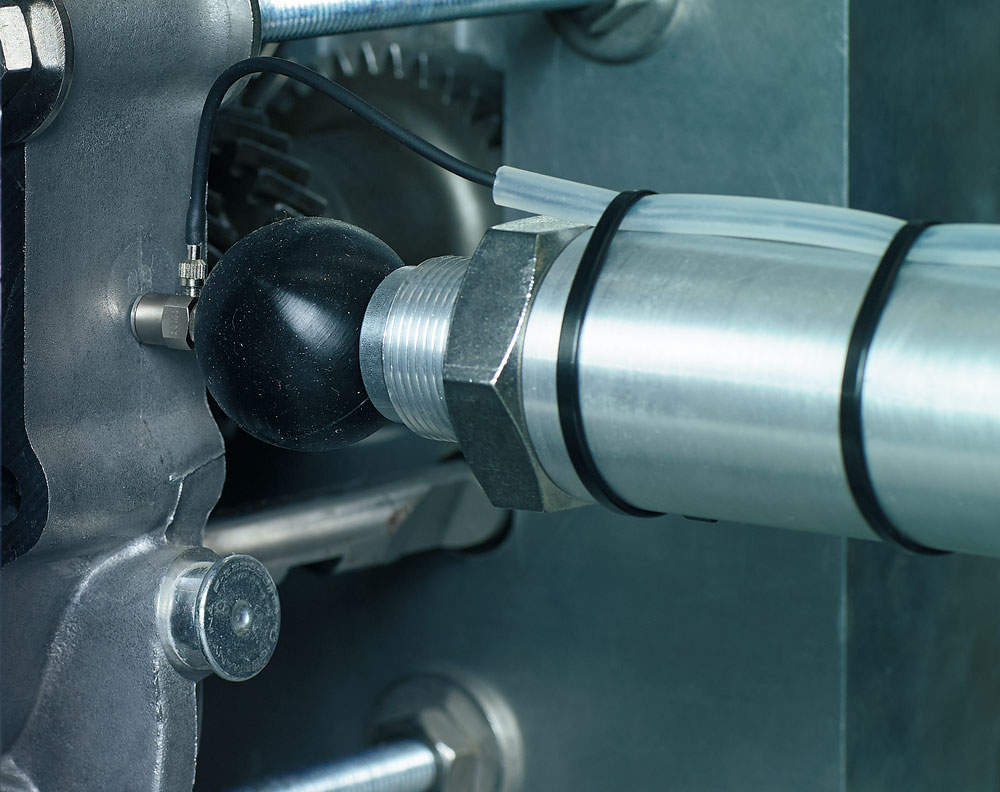

The best and most successful sensor worldwide for end-of-line testing in manufacturing companies in the automotive industry and their suppliers: Discom structure-borne sound sensors BKS03 and BKS10 measure vibrations directly on the test object – which makes them independent of the noise level in production.

Reproducibility of measurements

BKS sensors are developed for the requirements of end-of-line testing of . These accelerometers are generally automatically pressed onto the test specimen in the end-of-line test. The Discom solution is at today’s state of the art technology and thus replaces earlier spring-loaded sensors. Outdated spring-loaded sensors do not gernerate precise measured values or guarantee reliable reproducibility of measurements and there is barely any correlation between measured values of permanently mounted vs spring-loaded sensors. On the other hand, modern Discom sensors provide reliable and reproducible measurement accuracy. BKS sensors provide manufacturing companies with state of the art measurement technology and provide exact measured values that can be used to safeguard and improve the company’s manufacturing quality.

Excellent measurement results

This is where Discom BKS sensors show their strengths: The light sensors with optimized contact surfaces are pressed onto the test specimen with an elastic silicone body. The measurement results they provide are just as reliable and high-precision as screwed sensors. The low weight of the sensors offers an additional advantage: They are ideal for quality control of smaller test specimens. Of course the necessary cycle times in the second range are possible.

For harsh industrial applications

At the same time, BKS sensors are also optimized for harsh industrial applications: The silicone bodies are not subject to any wear and thus guarantee a long operating lifetime. The sensors are electrically insulated and suitable for a wide temperature range.

Standard in the automotive industry

Due to these enormous advantages, Discom BKS sensors have become the standard for many automobile manufacturers.

Application area

Quality assurance of large and small test specimens

- Transmission tests through motor tests and on to modern eDrive applications

- Used for testing pumps, turbochargers and other units in automotive applications

- Actuators and smaller electric motors

- Special solutions for your application are also possible

BKS03 allround sensor

BKS03

Allround sensor with a wide range of application

The standard for automatic testing with accelerometers: The BKS03 consists of a spherical silicone spring element with low Shore hardness. This element has a holder on the top for the exchangeable accelerometer. As the BKS03 is compatible with various charge and IEPE sensors, sensitivities between 10 and 250mV/g can be implemented. Due to the good coupling of the sensor to the test specimen, the sensor has a linear frequency range up to 14 kHz.

BKS03: Specifications

Sensitivity:

10 mV/g bis 250 mV/g

Frequency range:

up to 40 kHz, linear up to 14 kHz

Dimensions:

diameter 34 mm and length 97 mm

IEPE:

Compatible with all measurement systems with IEPE (ICP®, CCLD®) input

BKS10 compact sensor

BKS10

Compact sensor for limited installation spaces

The BKS10 has the same basic properties as the BKS03, except that the shape of the silicone spring element has been adapted to meet the new requirements for compact design. Special sensors are used which enable protected cable routing within the spring element. With a mounting adapter, BKS03 sensors can be exchanged 1:1. This enables fast refits of existing assembly lines for new requirements.

BKS10: Specifications

Sensitivity:

10 mV/g bis 25 mV/g

Frequency range:

up to 40 kHz, linear to 14 kHz

Dimensions:

diameter 18 mm and length 65 mm

Optimal for limited installation spaces:

small diameter

IEPE:

Compatible with all measurement systems with IEPE (ICP®, CCLD®) input

BKS03 / BKS10 with triaxial sensor

BKS03 triaxial / BKS10 triaxial

Both BKS types are available with triaxial sensors. This makes it possible to measure the X, Y and Z axes simultaneously.

Your benefits

Your benefits

Compact sensors for acceleration measurements

- Industrial precision: linear frequency response up to 14kHz

- Damping: Movements of the test specimen are compensated

- Decoupled: Test bench vibrations are effectively decoupled

- Rugged: Stainless steel contact plate

- Insulated: Electrical insulation of the sensor

- Variable: The right design for every application

Your advantages

Your advantages

Sensors with long service life for cost-optimized quality assurance

- Attractively priced: Sensors for cost-optimized quality management

- Long service life: The silicone element does not age

- Compatible: With every measurement system with IEPE (ICP®, CCLD®) input

- Fast: Short cycle times due to high elastic silicone

Downloads

Product Sheet Sensor Sets

Have we caught your interest?

Do you have any questions?

Would you like a consultation?