Finding production errors reliably

Actuators are used in numerous places in vehicles, for example for window lifters, mirror adjusters or tailgate openers. With the quality awareness of customers and especially for quiet electric vehicles, the requirements for the quality of actuators are also rising. Acoustic measurements and analyses with the Discom system of sensors and evaluating software reliably find production errors in end-of-line testing and provide the crucial component for safeguarding and improving manufacturing quality.

Measurement simulates human hearing sensation

Annoying noises from actuators are often loud and unpleasant for humans. They must be measured and analyzed from the viewpoint of psychoacoustics. Discom noise analysis therefore simulates the human hearing sensation and “listens” inside the closed system.

Production errors in actuators

The Discom system accurately finds production errors in the EoL testing of actuators like:

- on electric motors

- on transmissions, threaded rods and worm gear drives

- on springs and other expanding and contracting components

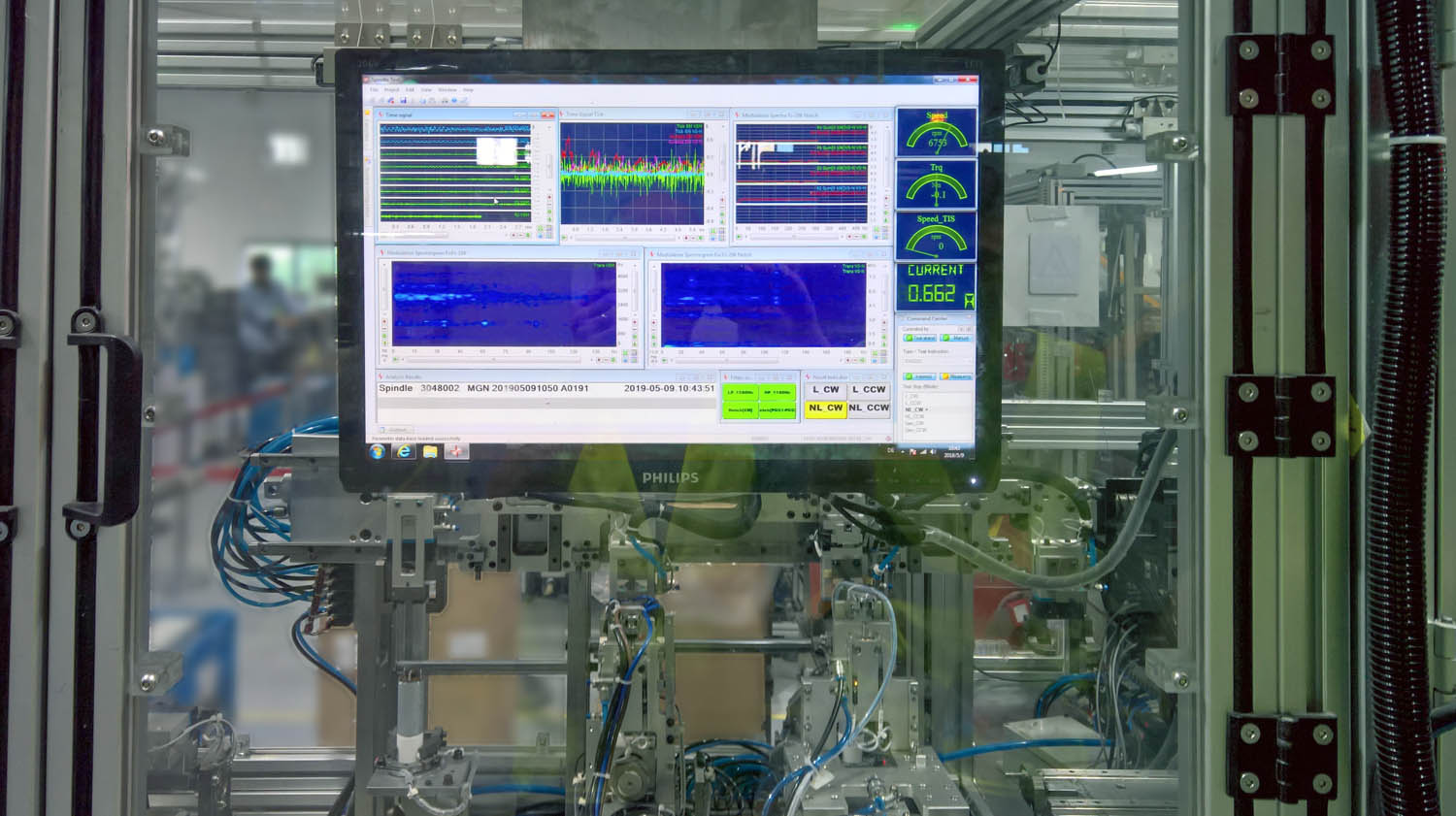

TasAlyser software

Measurements are analyzed with the Discom TasAlyser software. The software already has an extensive parameter database with all necessary characteristic quantities for testing actuators. The Discom analysis tools and results database make it possible to monitor production and recognize trends.

Production analysis

WebPal Production Statistics from Discom helps users to track trends, allowing them to detect problems that will occur at an early stage, before they become a true problem.

Discom sensors for acoustic measurements

Für die Aktuatoren-Prüfung bietet Discom unterschiedliche akustische Sensoren an. Alle liefern selbst bei lauten Umgebungsgeräuschen Messergebnisse akkurat ab.

BKS structure-borne sound sensor

For fixed test specimens with a surface for pressing on the sensor

MVS magnetic accelerometer

For test objects that move or for which the mechanics of pressing on a sensor are not possible

Your benefits

Your benefits

Measurements of entirely different test specimens

- Versatile application: Discom sensors are suitable for very different test specimens

- All-in-one solution including sensor, frontend and software

- The TasAlyser software has a results database with all relevant characteristic quantities

Your advantages

Your advantages

One measurement for all components

- Acoustic measurement acquires noise anomalies of all elements of the actuators

- Fast, complete analysis of the test specimens

- Efficient quality assurance directly in production in the EoL test bench

- Increased manufacturing quality