Pinpointing manufacturing errors

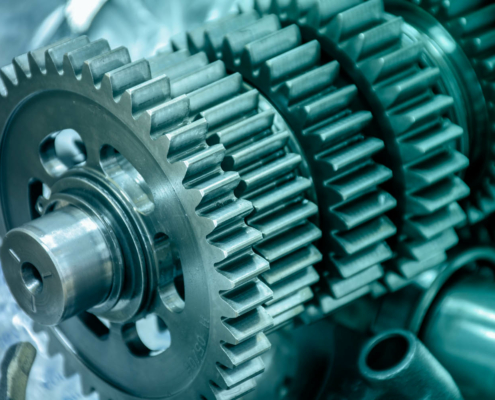

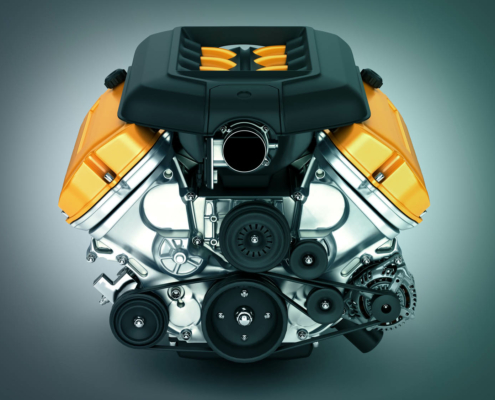

The Discom system for acoustic measurement and analysis, consisting of sensors, frontend, software and a Big Data option, is successfully used by many well-known manufacturers of vehicles and components. The end-of-line testing of assembly units and components is the greatest strength of the Discom system. The wide range of measurement and analysis methods make it possible to pinpoint the exact cause of problems and faults. The entire production process can be monitored using the results database and production statistics.

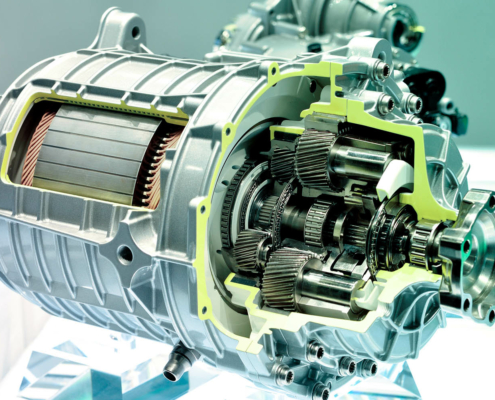

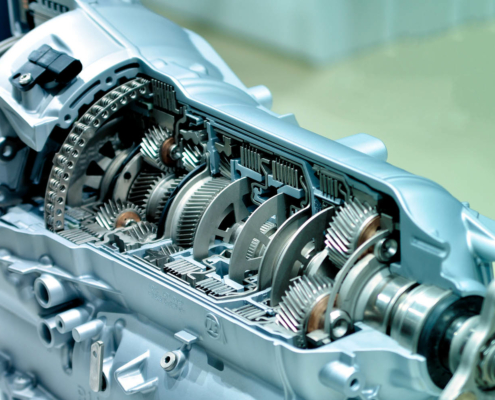

Discom complete solution for end-of-line testing

Discom offers the “ROTAS” complete solution for end-of-line testing. It consists of sensors, frontend, PC rack and software. For this solution the test specimens are fitted with sensors. The sensor signal is digitized in the Discom “TAS” data acquisition system and then forwarded to the analysis software on the PC.